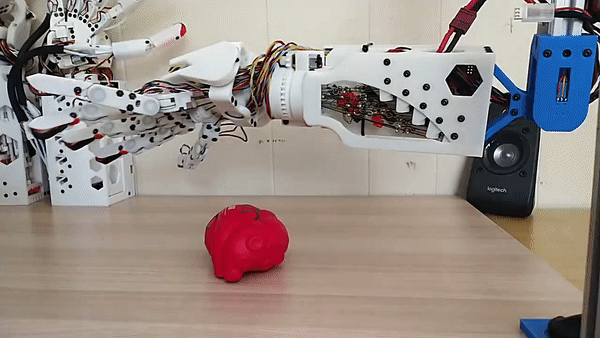

Hextech Mechahand, Alpha Release

I designed an open source robotic hand as a low cost standard for reinforcement learning on dexterity. The hand has 20 degrees of freedom, mimicking a human range of motion. Each of the joints has position feedback and force sensing, with 6 extra pressure in the finger tips and palm. All electronics feed into a compact PCB with WiFi connectivity. The bill of materials is just under $300 amortized over 5 hands.

Hextech Mechahand

The robot hand is targeted as an accessible standard for reinforcement learning research as it has full state feedback and complete range of movement with an opposable thumb and curling pinkie side of palm. Compared to other 3D printed hands, the Hextech hand has position sensors and bearings embedded in each of the finger joints. Since the actuating motors are placed on the forearm and tied with stretchy nylon wire tendons, the in-place position sensing allows for accurate state feedback. The custom PCB includes current sensors for each motor to judge power use and rough force sensing, if adjusting for ohmic resistance and tendon friction.

The demo uses a Leap Motion sensor, which is a little box with cameras under my hand that uses machine learning to model my hand position. Unfortunately the sensor is not very good, especially for fine finger movements where the fingers are partially occluded due to the hand pose. For example when grabbing a pen the hand is sideways to the camera, hiding half of the fingers. Nevertheless I manage to grab a pen and scribble on a page.

The PID loop runs at 69Hz and limits burst and continuous current use for each actuated joint. This limits the forces applied by the hand for safe handling as well as safety of the hand. The hand was in fact strong enough to tear itself apart, but fingers crossed that extra thickness and higher infill will fix the weak point. The WiFi Websocket loop is currently limited to 10Hz. I’m working on the MQTT interface and loop optimizations, expecting to improve the remote loop to 30Hz and the inner loop to 200Hz.

The hand is built using off the shelf components and a 3D printed body at an amortized cost of 300 USD per hand, requiring 30 hours of assembly time. Included in the cost is the custom PCB designed for automated assembly. All design files for the mechanism, the control circuit, and driver code is open sourced on github.